| Build History Phase 4 | ||

|

Benefits Front Installation Rear Installation Why do this Installation of heat exchanger Installation of extra radiators Reasons for retrofit Supplied Kit Completed install Options Supplied Kit Completed Install

|

This section will detail some general advances in the design and functionality of the car to enable other forms of motorsport to be enjoyed beyond only drag racing. (Click on pictures to see larger version) Enabling manual gear selection on the automatic transmissions The existing automatic setup was great for drag racing and normal driving on the street but did not allow manual downshifting which limited the use on any form of driving where manual gear selection would be paramount for both engine braking and corner exit gear selection. To resolve this issue I purchased a TCI Streetfighter ratchet shift. This would allow manual shifting of the transmission from D into 3,2,1 and of course 1,2,3,D in a simple forward\backwards motion similar to a sequential manual gearbox. Although this will not have the same responsiveness as an actual manual gearbox it should suffice to enable the car to do motorsport events where manual gear changes are required. The TCI shifter before installation, it's quite a nice piece of engineering design. Once installed in the car it looks much nicer than the old Daewoo shifter that was there previously. Installation however didn't go quite as smoothly as hoped since asking if this was specifically compatible with my 4T40E tranmissions and being told yes, I (stupidly) assumed that the correct connection parts would be included. Despite the kit containing the appropriate adapters for loads of transmissions there was nothing for my model or indeed any FWD transmission. I had to fabricate a plate to hold the linkage cable in place and also modify the supplied shift plate to fit correctly onto the transmission. Somehow (mostly luck) I managed to get one of the other plates modified on the first attempt after some gental (ie abusive) filing followed by welding and filing again to fit. Before, nowhere near the correct alignment: After: This was a fun job trying to get a plate made up to hold the shifter cable and be able to drill the existing bracket in place without taking this bracket off. Result at the end though, successfully selects all gears. Just need to work on the rear one next which will take a bit more design improvisation.

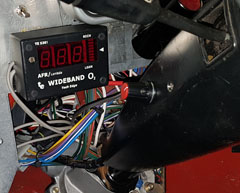

Balancing the water cooling systems Cooling the rear engine has always been problematic, with various enhancements around the airflow into the rear compartment and the fan ducting it isn't too bad but will eventually overheat (or as a minimum have the fan on constantly trying to cool the rear radiator) if driven 5+ miles with both engines in use and quicker if on a track. Initially I had though to share the water between the two engines but had concerns that this may cause flow path issues and then had an idea from a combi boiler to use a water heat exchanger. This would share the water cooling from the front engine with the rear without the actual water being shared and hopefully enable more stable temperature control on the road at least to start with. I dont't think this will allow full track sessions initially since the front cooling system will be unable to cope with that amount of extra heat dissipation currently (i'm going to try and get some more radiators in there somehow) but it should be at least sufficient for shorter sprints and hill climbs for now without worry. This is the new heat exchanger, it's a 210kw unit so should transfer the heat fairly well to assist the rear cooling. I have also added an extra radiator (actually quite a large heater matrix from a ford of some derivative) into the front corner of the passenger wing area. Still needs to be boxed in to force the air through from the front at this point and there should be another one fitted in the driver side. Hopefully with the addition of these extra rads the cooling will be much improved since the two of these smaller rads are about 75% of the existing front primary radiator but double the thickness and double the density of cooling fins. Added a 6" fan also to the new little rad which is controlled along with the primary front fans. Heat exchanger installed and piping currently through the car with insulation installed to stop it heating the inside of the car too much like it used to do many years ago. Heat exchanger seems really efficient so will look forward to testing it out on the road for a long distance twin engine trip which used to be impossible for more than about 5 miles due to the excess heat build up at the rear. Still likely not up to full track sessions just yet as think it will require another rad added to the front setup to cope and also some oil cooling. Think i'm getting into fan overload up front, might need an extra circuit to power this lot soon when the next rad is added lol The original rear engine water hose that connected to the back of the water pump was replaced since the 2 outlets were too small to ensure good coolant flow from the heat exchanger. This new copper one uses 15mm connections so much better than the old one which was 8mm bore.

After a few sessions at Curborough and also the hill climb at Shelsley Walsh I found it quite hard to get a good responce to steering in the corners due to quite bad torque steer and also being generally very heavy. Once the manual quick shift is installed I would need to be able to hang on to it with one hand and that would be quite unsafe as currently a small change in camber under heavy acceleration can yank the steering even with 2 hands quite harshly. The power steering from a Corsa B should resolve this issue and make the car much easier to hang on to. Rather than try and make the Corsa setup fit from scratch (which would have been cheaper, DIY would come in at around £100, a complete kit was £300) it was easier to purchase a ready made kit to save much time and possible errors adding yet more delays. This retrofit will also provide an opportunity to strengthen the mount point for the steering as it just didn't feel solid enough for me when used with a lowering bracket. Finally all installed, it's adjustable via a control knob on the steering column. Still to test on the road but in the garage you can turn the wheel with one finger when on max and it barely feels like there is any assistance on minimum so should be good once i've got used to the correct assistance setting for each type of driving. Had to modify the mount point instructions on the kit due to the fact I had slightly moved the steering rack so the side strengthening bracket wouldn't how originally intended but it's more solid than before. Eventually I may replace the manual assistance control by using the speed outputs from the transmission which would enable the assistance to vary automatically based on speed but manual will suffice for now. Was really good on first trial, although you do lose a little of the feedback through the steering to detect traction loss it is so much easier to control the torque steer under heavy acceleration with slight camber changes in the surface and also snatch when exiting corners.

For drag racing and the shorter sprints the metro turbo 8.4" 4 pot brakes have been ok but for longer sprints\hillclimbs these really start to struggle due to the increased weight of the car with 2 engines and heavy automatic transmissions. I had been looking around for upgrades to the 8.4" discs and was thinking about creating something myself from adapting various parts from other cars to increase the disc size. This would have been the cost effective option but to save time have decided to go for an off the shelf conversion from ZCars as this would give me 270mm discs and lightweight calipers. Also since braking is very important from a crashing perspective though it a better idea to have professionally machined components rather than something I cobbled together. Brake kit to be fitted Disc comparison Metro Turbo and ZCars, just a bit bigger :o) The Metro turbo disc actually wasn't 8.4" but more like 8 4/16ths" so in reality more like 8.25". The ZCars discs are 10.2" so should provide much more efficient braking. Weight wise there is a small saving there too on unsprung weight, the Metro setup was 7.7Kg with the ZCars being 7.2Kg. Unfortunately the bigger discs will actually increase rotational mass when accellerating in the lower gears but shouldn't be too bad. Fitted into place to check the clearances (which all look good). I have also now removed the twin brake cylinder arrangement that was used originally and returned to a single master cylinder and pressure bias valve for the rear. I would have used this option in the first place but with the throttle bodies there wouldn't have been clearance for the master cylinder however with the Evo inlet there's plenty of clearance. This has also enabled the servo assist to also be used at the back to which should improve braking balance. Following some road testing the new brakes are in another league compared to the original 8.4" ones, not just in coping with longer amounts of braking effort without heat issues but in the general feel, responsiveness and progressiveness. I think that the servo needs to be changed back to a lower ratio as with a 3:1 servo the brakes are now just too sensitive. Will likely fit a spare 1.5:1 servo that I already have spare from a previous setup. Really looking forward to testing these at the track.

|

|